Plastic caissons

We produce two models of plastic caissons:

The plastic caisson is designed for the formation of a water-free processing chamber in water-saturated soil. Caissons also function as a protection for wellhead systems from mechanical impurities (leaves, soil, grass, other objects, etc.), surface- and groundwater, precipitation, temperature fluctuations.

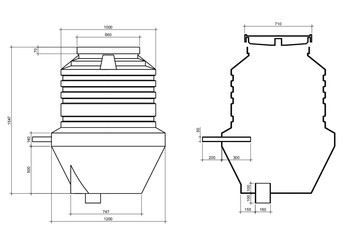

| Name | Height, mm | Diameter, mm | D of throat, mm | Wall unit sickness, mm | Price |

| Caisson flat-bottomed | 1580 | 1000 | 660 | 8 | 21250 uah |

| Caissons conical | 1550 | 1200 | 660 | 8 | 16346 uah |

Caissons of any diameter and height are produced by means of soldering nozzles onto plastic wells. Feel free to call (044) 492-82-06.

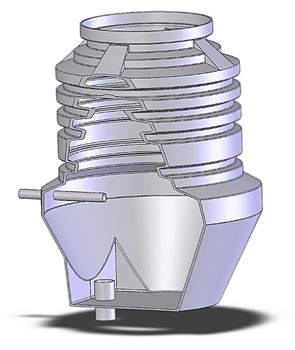

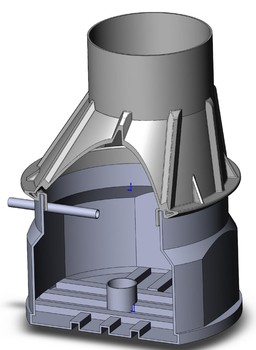

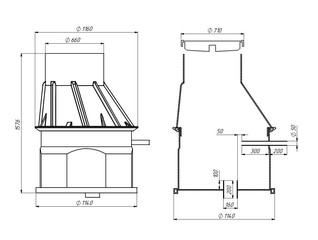

A nozzle of 160mm is soldered onto the bottom of caissons to attach the casing, and a nozzle of 50mm is soldered onto the lateral surface to connect a pressurized water system. Caissons are equipped with a plastic lid.

Nozzles in a flat-bottomed caisson

The wall thickness of 8 mm provides a reliable thermal and waterproof effect. There are no seams on the surface of caissons which ensures impermeability. Caissons of our production are made of high-strength, eco-friendly polyethylene, resistant to corrosion and temperature fluctuations.

Installation guide

Caissons are set in a prepared foundation pit on a rammed sand cushion not less than 150 mm thick. The distance between the caisson and the pit wall(at least 150mm thick)is filled with layers of sand proportionally mixed with cement. The amount of cement per 1m3 of sand increases according to the ratio of the threat of flooding the caisson by groundwater. In the case of groundwater penetration, the lower part of the caisson will be anchored by means of concrete casting.